Job placement and return to work considerations are determined in many cases by the results of lifting capacity tests. Having sufficient strength to perform a job, particularly a labor-intensive job, has been a focus of many FFD tests in the past and present. As physical abilities testing progressed in response to legal requirements to avoid job placement discrimination, it became apparent that functional capacities testing needed to reflect the real workplace. Accordingly, it was evident that as job demands and characteristics varied, so must the means and methods of physical agilities testing. Therefore, evaluating the worker’s capacity to perform the essential physical demands of a job such as lifting has become one of the key discriminators in determining safe functional capacities for work.

Research has demonstrated that reductions in the incidence of musculoskeletal injuries can occur when standardized strength tests are used in the employment process. Matheson, Isernhagen, and Hart 1 demonstrated that the use of lifting tests had a positive relationship to the return to work levels of injured workers. Decreased trunk flexibility and weak trunk strength were found to contribute to lower back injury. Workers, who could demonstrate strength capabilities exceeding the strength required in the performance of their jobs, had a lower incidence and severity of musculoskeletal injury.

The study by Chaffin and colleagues2 assessed the correlation of strength to injuries on the job using isometric tests to determine whether workers who demonstrated insufficient strength to meet the physical demands of the job were at an increased risk of injury. Based on the results of this study, the authors believed that the evidence for strength testing and placement was substantial and opined that an employee selection program should use a strength performance criterion in the testing process.

In a study by Keyserling3, the utility of strength testing to identify workers at higher risk for injury on the job was analyzed. The results indicated that significant strength differences were observed overall between males and females, and all employees assessed to fall in the weak test group experienced the highest incidence of musculoskeletal problems in most of the test samples. The results suggested that in cases where job redesign is not feasible, an interim solution to the problem of work related morbidity is to establish a program for selecting workers based on their ability to perform the strength requirements of their jobs.

The accuracy of strength testing is dependent upon the quality of the systematic evaluation of the worker, performance standards of the task, the degree of inter-rater reliability of the tasks and the skills of the examiner. In addition, Gross and Battie4 found that the assessment of manual material handling is enhanced when the assessment occurs over more than one occasion in order to capture the variability in function.

What Type of Lift Test is Best?

Lifting capacity tests conducted in FFD examinations have used various methods of measuring lifting strength to include primarily isokinetic, isometric and dynamic lift tests. A FFD evaluator should consider which of these methods actually best simulate a “real-world’ job task and reliably predict the ability of the test recipient to lift safely on the job.

Dynamic lift testing involves lifting a weight through space in the same way that the lift is performed on the job. Although this is obviously the most content valid way to test lifting, there have been advocates of isokinetic and isometric lift testing who criticize dynamic lift testing as lacking inter-rater reliability due to variance in the observation of body mechanics while lifting. This criticism may also stem, at least to some extent, from a financially driven bias related to justifying the purchase of expensive computerized isokinetic and isometric equipment in clinics. Studies have shown that a dynamic lifting protocol can be standardized and provide a high inter-rater reliability.

In essence, research studies indicate that isokinetic and isometric strength testing do not accurately predict back injury and fail to demonstrate value in employee selection.5 In a study comparing isometric strength and dynamic lifting capacity in men with work-related low back injuries, the results indicated low to moderate associations between isometric strength measurements and lifting capacity. In a study involving 107,755 male and 23,078 female prospective workers isometric (static) strength testing was analyzed to determine accuracy in predicting dynamic lifting capacities during post-offer employment tests. Subjects were tested for strength using three standard static lifts (static leg lift, static arm lift and static torso lift) and then tested for maximum lift capacities using dynamic lift tests. The data confirmed only modest correlations between isometric and dynamic measures and found that the standard errors of estimate for all isometric-to-dynamic predictions make such predictions meaningless for the practical purpose for which they are most commonly used such as assessing the abilities to lift safely at work. Potential safety concerns related to static lifts, particularly the torso lift, as reported by previous investigators, employers, clinicians, and risk managers indicate that static (isometric) lift tests are not appropriate for making predictions relative to dynamic lifting capacity.6 In general, these studies suggest that estimates of functional lifting capacity should not be based on isokinetic or static (isometric) measurements alone.7

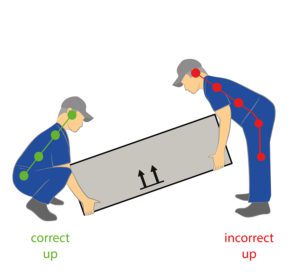

In light of legal requirements that functional job placement tests represent tests of valid essential job demands (i.e., that test constructs have content validity), isokinetic and isometric lift tests must be used with caution as discriminatory tests for ability to lift at work safely. Dynamic lift testing, which simulates the type of lifting actually performed on the job, offers a more content valid method to assess a person’s physical capacities to perform lifts on the job. If a test recipient cannot dynamically lift a certain amount of weight during a FFD test, it can be safely assumed that the test recipient will not be able to safely lift the same amount of weight on the job. In addition, dynamic lifting allows the FFD evaluator to better determine whether or not a test recipient can perform a lift safely. For example, dynamic lifting allows the evaluator to assess the test recipient’s body mechanics throughout the entire range of lifting. Isokinetic and isometric lift testing do not allow this assessment. Compensatory motions of the body or inability to maintain safe body mechanics throughout the entire range of lifting can indicate weakness or impairment that poses an immediate threat of harm to the body when lifting on the job. Also, heart rate and blood pressure responses to dynamic lifting will be more representative of the actual cardiovascular responses to lifting on the job than isokinetic and isometric tests.

It should be recognized for the sake of test standardization and safety, that lift testing in the clinic will rarely present the same degree of physical stress on the body as actually encountered in an uncontrolled or changing work environment. Thus, inability to lift safely in a controlled clinical environment can be accepted unequivocally as a reliable indicator that the test recipient will be unable to lift safely in an uncontrolled environment of the job.

Recommendations for Testing

In order to conduct tests that most closely replicate real-world lifting tasks, the FFD evaluator should use dynamic lifting tests that reflect the real-world parameters of the job task as closely as possible without exceeding any parameter that would make the lift test more difficult to perform than is actually required for the job. These parameters include:

- Weight and dimensions of the material being lifted

- The frequency of the lift tasks

- The vertical starting distance from which the lift is initiated

- The termination distance of the lift

- The angular rotation of the lift

- The quality of coupling of the lift

In certain instances, it will be difficult, if not impossible to exactly simulate a lifting task and the environment in which the lift may take place. Therefore, it is imperative that the FFD evaluator be careful to both avoid any lift test that does not correlate reliably to dynamic “real-world” lifting tasks and to avoid using lifting test parameters that exceed the actual job demands.

In summary, the FFD evaluator must be certain to use content valid lift tests that avoid physical demands exceeding those required in real-world job situations. Any screening test used to match an employee to the job should be designed in such a way as to at least correlate a failure to safely lift in the clinic to failure to safely perform the same type of lift at work. For example, lifting 50 pounds in a standardized lift box with handles from the floor to waist may be used in a clinic to test whether a person can safely lift that same amount of weight at work. However, one may ask, how can such a lift test be considered valid if the actual material being lifted that weighs 50 pounds at work does not have handles, is shaped differently and is handled in a more hostile environment? The answer to this question relates to the test outcome predictability. When a test recipient is unable to perform a lift test in the controlled environment of a clinic, it is very reliable to predict that the test recipient will not be able to safely perform a lift involving the same weight in actual work environment. Therefore, when conducting lifting tests for the purposes of new hire, post-offer job placements, it is important to simulate the various parameters of a lift as closely as possible to real-world lift tasks. However, the lift test must avoid any demand that exceeds the job demands to avoid unfair disparate discrimination in lift testing.

References:

- Matheson, L.N., Isernhagen, S.J., & Hart, D.L. (2002b). Relationships among lifting ability, grip force, and return to work. Physical Therapy, 82(3), 249-256.

- Chaffin, D. B., G. D. Herrin, W. M. Monroe. Preemployment Strength Testing – An Update Postion. Jnl Occup. Med. Vol. 20, No.6, June, 1978

- Keyserling, W. M., Strength Testing/Employee Placement on Physically Strenuous Jobs. Symposium on Occupational Safety Research and Education, Division of Safety Research and Division of Training and Manpower Development, NIOSH, U.S. Department of Health and Human Services, DHHS (NIOSH) Publication No. 82-103, 1982

- Gross DP, Battie MC (2002) Reliability of safe maximum lifting determinations of a functional capacity evaluation. Phys Ther 82: 364-71

- Battie, M., S. Bigos, L. Fissher, T. Hansson, M. Jones, and M. Wortley. Isometric Lifting strength as a predictor of industrial back pain reports. Spine 14:851-856, 1989

- Feeler, L. , James D. St. James, J. D., Schapmire, D. W., Isometric strength assessment, Part I: Static testing does not accurately predict dynamic lifting capacity. Work 37 (2010) 301–308

- Rosecrance, J. C., Cook T. M., Golden N. S. A comparison of isometric strength and dynamic lifting capacity in men with work-related low back injuries. J Occup Rehabil. 1991